Photonic coupling

enabled by aligned 3D nanoprinting

From prototyping to production

with high-precision 3D optics printing

Powered by the cutting-edge technology of 3D printing by 2GL®, Quantum X align produces freeform microoptics with exceptional shape accuracy and surface quality. Dynamic voxel size control during the printing process significantly reduces the number of layers, thus boosting printing speed without compromising precision or quality.

Aligned optics printing with A2PL®

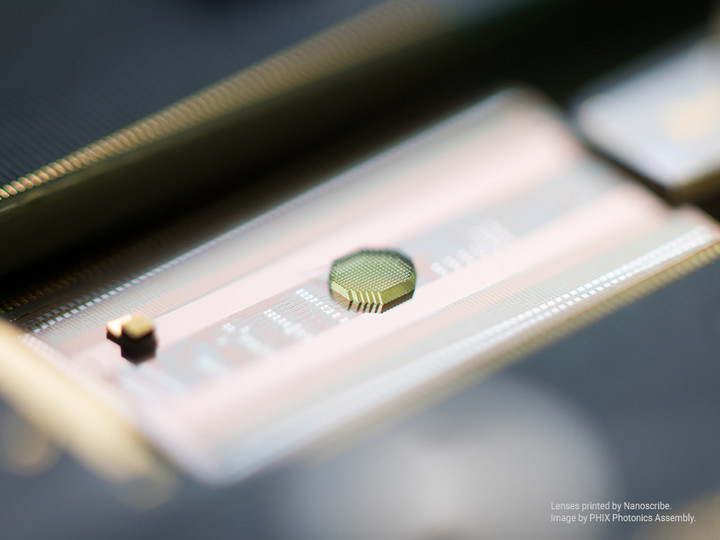

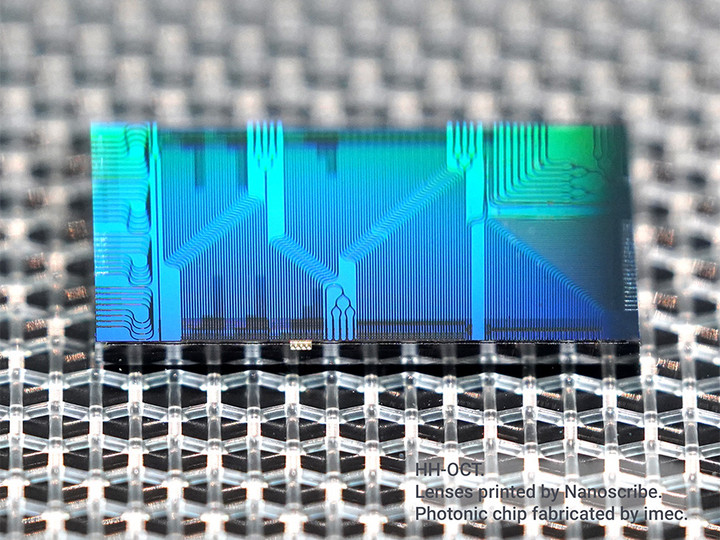

With Aligned 2-Photon Lithography A2PL®, Quantum X align automatically detects chip edges, fiber cores, fiducials on chip surfaces, on wafers, and on prestructured substrates. It then prints freeform microoptics directly in place with nanometer-scale alignment accuracy, ensuring that the optics are printed aligned to optical axes. This makes the printer ideal for photonics packaging, saving time and costs for additional fabrication and assembly steps for mounting or fixation.

Aligned 3D printing

of freeform optics on chips and fibers

Quantum X align in facts and figures

Included features

-

Aligned 3D printing, e. g. high-precision optics aligned to fiber cores, chip surfaces and edges, or fiducials using Aligned 2-Photon Lithography (A2PL®)

-

Up to 60 times faster speeds at superior quality compared to classic 2PP, achieved through 3D printing by 2GL® (Two-Photon Grayscale Lithography)

-

3D printing on different material platforms for photonics packaging, e.g. SiN, Si, SOI, GaAs, LNOI …

-

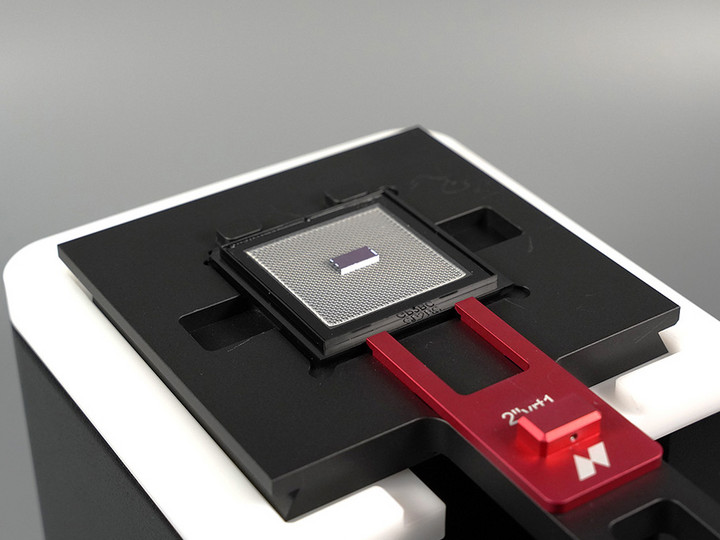

Automatic printing aligned to fiber cores enabled by the Fiber Printing Set

-

Automatic 3D mapping of complex substrate topographies enabled by the Chip Printing Set with a confocal detection module

Optional features

-

Rapid and accurate surface patterning enabled by Two-Photon Grayscale Lithography (2GL®)

| 3D alignment detection accuracy 1 | down to 100 nm in x/y direction |

| Surface roughness Ra | down to ≤ 5 nm |

| Shape accuracy Sa | down to ≤ 200 nm |

| Feature size control | down to 100 nm in x/y direction |

| Typical processing time | 10 min. for 8x lensed fiber array |

| Achievable coupling losses 2 | down to ≤ 1 dB |

Peak values, only achieved under specific conditions such as printing parameters, print heads, photoresins, and designs.

1 With confocal detection. Accuracy depends on selected print head

2 Best case for typical applications, depending on design, substrate quality and measurement method

| Substrates | Microchips, TO cans Single cleaved fibers (single-/multimode/polarization-maintaining) Fibers in FC or SMA connectors Fiber arrays (v-groove) Wafers from 1” to 8” (25.4 mm to 200 mm) Glass, silicon, other transparent and opaque materials |

| Photoresins | Nanoscribe polymer photoresins Open for third-party and custom materials |

Enabling features for scalable

photonics and optics manufacturing

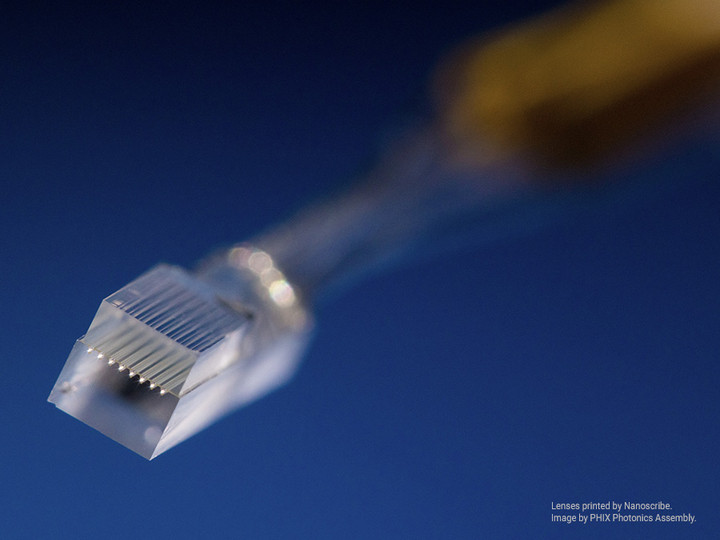

Joost van Kerkhof, Chief Operations Officer of PHIX Photonics Assembly

We are confident in Nanoscribe’s new, aligned 3D printing technology for producing lensed fiber arrays and lensed chips with virtually limitless optical designs.

Free Space Microoptical Coupling

Highly efficient solution for photonics packaging

Free Space Microoptical Coupling (FSMOC) offers a highly robust and efficient light coupling solution for photonic packaging and integration. Freeform microoptics fabricated directly on the optical interface of chips or fibers enable tailored beam shaping and mode field adjustments. This leads to relaxed alignment tolerances between optical elements and eliminates the need for active alignment, e.g. for fabricating optical interconnects.

FSMOC is flexible in use and can be easily tailored to meet application specific requirements.

- Cost efficient photonic packaging strategy

- Relaxed alignment tolerances for passive alignment

- Achievable coupling losses down to ≤ 1 dB

- Easy and quick adaptation to new requirements and applications

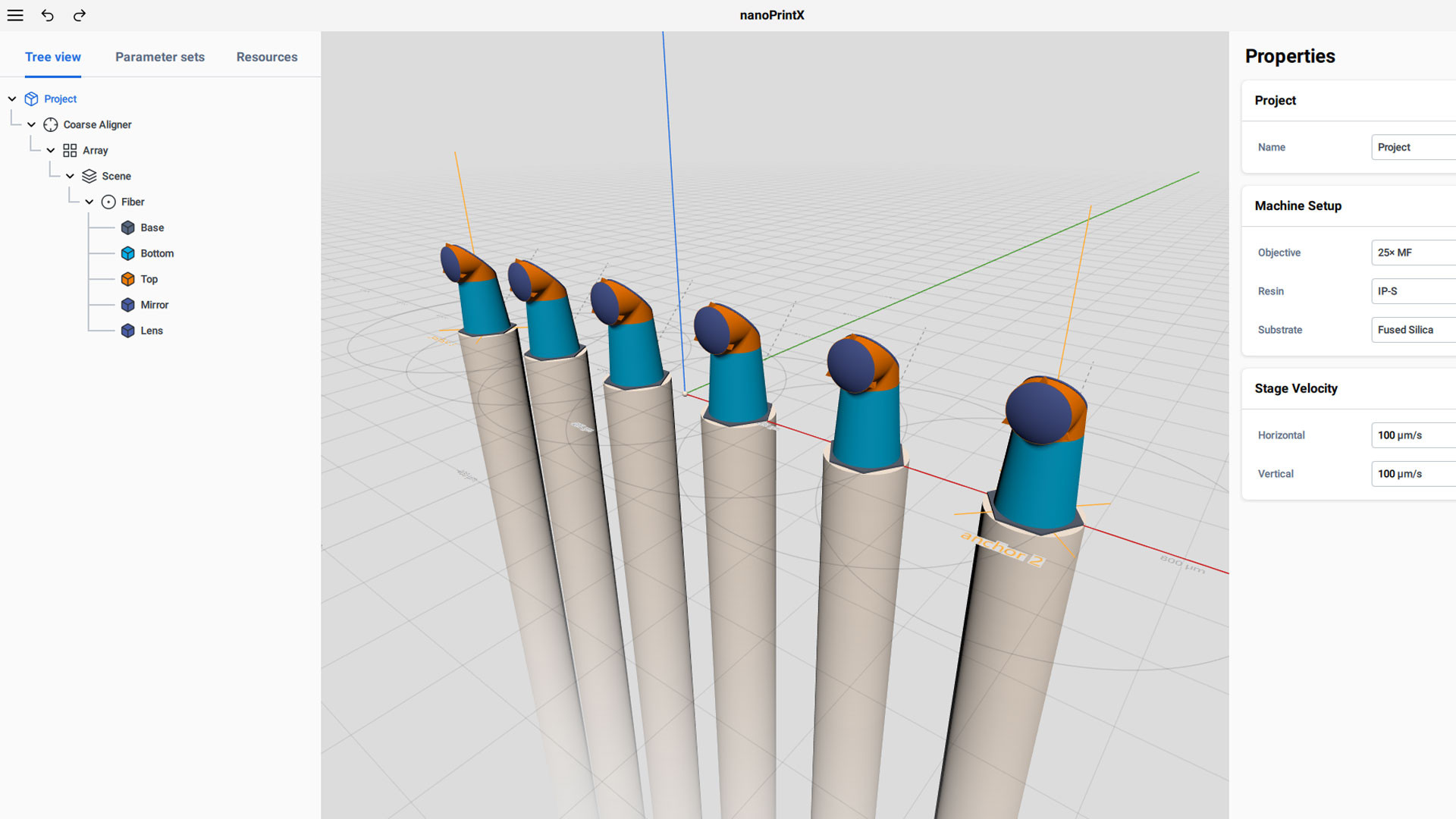

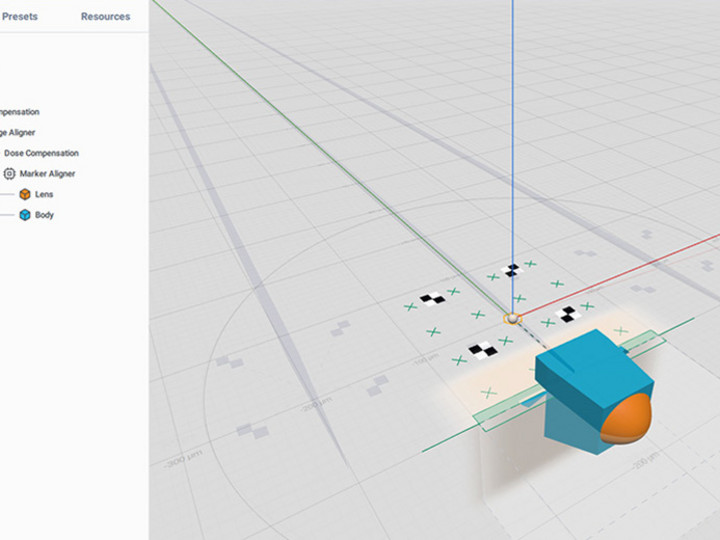

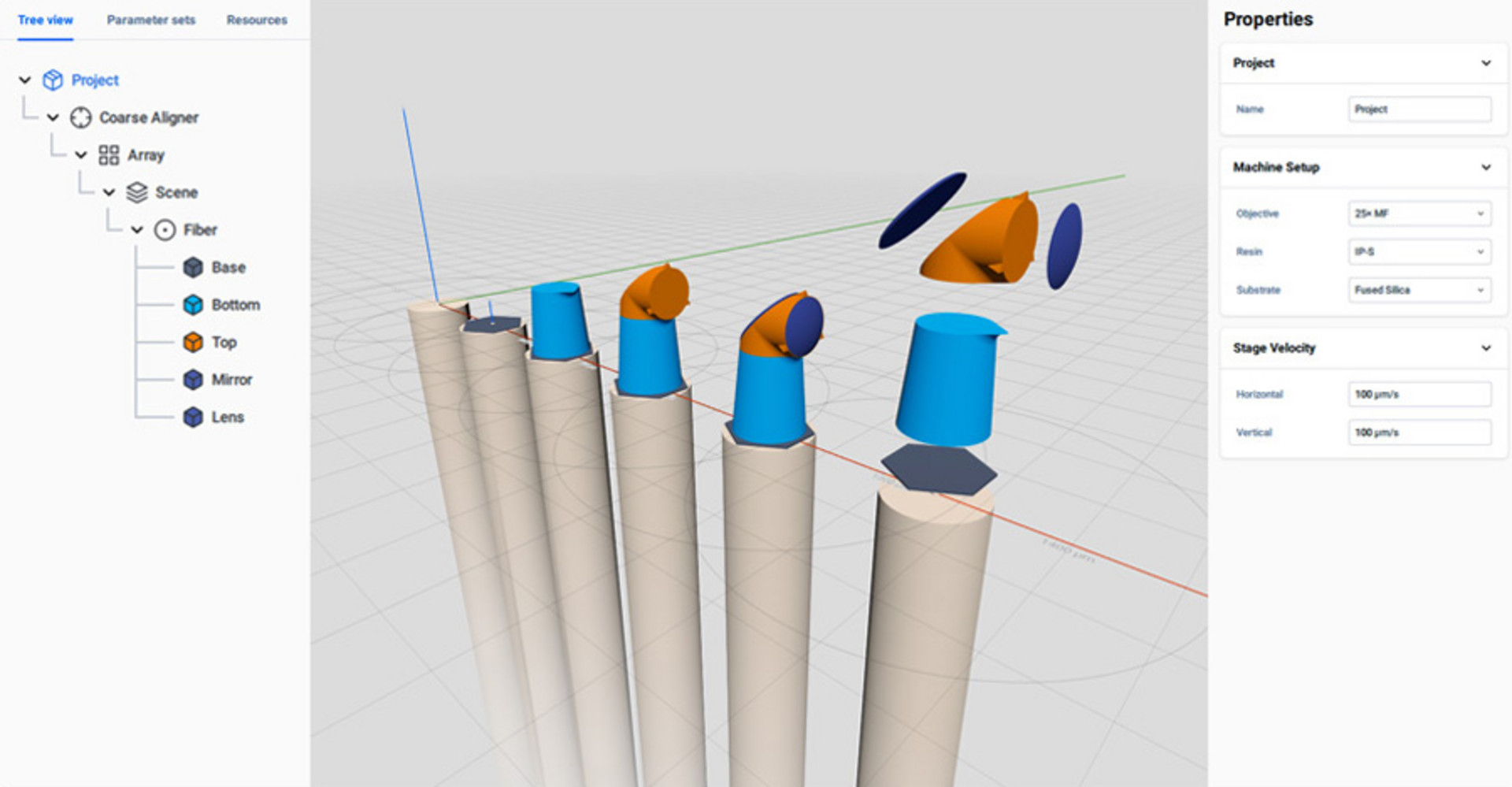

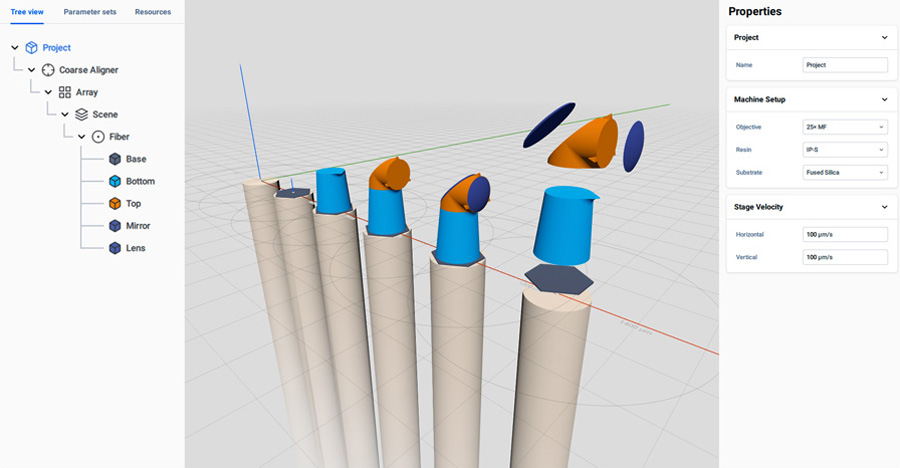

Set the scene with nanoPrintX

Compose and align your prints smarter

nanoPrintX is much more than a 3D printer slicer software. It is a game-changing tool to create sophisticated print projects for aligned 3D printing, supporting our revolutionary 2GL-technology. The underlying scene graph concept, a tree-like data structure that provides a hierarchical organization of all print-relevant objects and operations, enables an agile definition of what, where, in which spatial orientation and how to print. The intuitive software architecture, combined with a central rendering canvas, provides instant visual feedback on the position and spatial alignment of all elements relative to each other and to predefined positions or substrates.

Compose your print project with nanoPrintX: Define the print scenario by creating a virtual model of your specific substrate, such as optical fibers or photonic chips with individual alignment markers. Import your 3D print designs, use pre-installed simple geometries as building blocks, or generate spheric and aspheric lens designs with a parametric design tool in nanoPrintX. Assign pre-developed print parameters to individual designs as needed, and get the most out of your design with the brand new presets for 3D printing by 2GL®. Finally, simply upload your print project to Quantum X align and enjoy the results.

Start your print project via the touchscreen: The intuitive touchscreen user interface of Quantum X align easily guides you to successful printing. Register the starting positions on each substrate, double check using the high-resolution live camera view and start your print project. The system will then automatically align your prints with respect to your markers with submicron accuracy.

Stay connected with nanoConnectX: Start and monitor your print project from the office with the remote access software nanoConnectX. It brings all the control functions and display capabilities of Quantum X align’s front panel touchscreen to any computer connected online. The Quantum X align system is hereby well equipped for production environments and multi-user scenarios.

Software facts

nanoPrintX is available for all Quantum X systems. It enables easy and fast design of complex structures and offers special printing strategies for specific parts of a structure. It also supports structure-substrate aligned printing with nanometer precision and is powered by our latest printing technology, 3D printing by 2GL®, delivering superior quality at unrivaled speed.

Structures ranging from the submicron to the millimeter scale can be fabricated using nanoPrintX. Its easy-to-use tree node organization guides you in a few simple steps to set up print projects for aligned prints on optical fibers, on photonic chips and other pre-patterned substrates.

Key features

- 3D rendering canvas for composing and positioning structures relative to each other or to fiber cores, fiducials, and chip edges

- Easy creation of array configurations

- Intuitive organization of all print relevant operations in a tree node

- Ready-to-use parameter presets for optimal print results

- 3D printing by 2GL® for superior quality at unrivaled speed

- Fiducial detection via pattern matching

- Dose compensation for excellent results on substrate edges

- Fiber printing node for automatic fiber core detection and printing of optical structures

- Parametric lens design tool based on ISO standard 10110

Control and monitor the high-resolution 3D printing system using the 18.5-inch front panel touchscreen of Quantum X align with its graphical user interface (GUI). It guides you to a successful print in just a few steps: select your print project, then load your substrate and start printing.

Key feature

- Three live cameras to monitor the printing process in real-time from distinct viewpoints

- Virtual navigation camera (a 3D model of the print setup) allows for a precise and easy navigation on the substrate

- Easy stage control in all spatial directions moves the stage to any position on the substrate

- User-friendly print setup facilitates the workflow from the print project upload to the print execution

nanoConnectX is the remote access software for the Quantum X. It brings all the functions and display capabilities of the touchscreen to any computer connected online.

- Connect the Quantum X system to your computer, no matter where you are with the remote access software

- Use all features of the touchscreen to prepare, control and monitor your print jobs from any location

- Download and upload print projects directly from your computer

Explore Aligned 2-Photon Lithography

and Quantum X align in depth

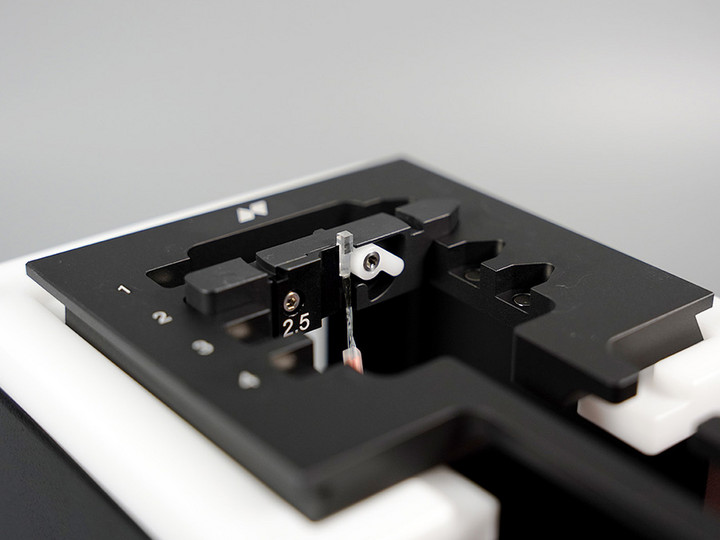

How is printing on fibers, chips and wafers done?

Nanoscribe’s substrate holders guarantee a precise fixation and enable to print on the facet of single fibers, fiber arrays and photonic chips. Furthermore, standard substrates such as wafers from 1” to 8” can be easily processed. Dip-in Laser Lithography furthermore enables high-resolution 3D printing on a wide range of reflective, transparent, and opaque substrates (e.g. glass and silicon substrates).

How to print optics precisely aligned to fiducials?

The 3D alignment of the print object is based on the high-resolution 3D topography mappings by the confocal unit. For the precise alignment of optical components on a photonic chip or a wafer of any material, smart software algorithms automatically identify fiducials, such as predefined markers and topography features. For example, the exact position and orientation of waveguides on a chip can be determined. A virtual coordinate system is then set to the exit of the waveguide, perfectly aligned with its optical axis and orientation. The desired optical components are automatically printed with respect to this coordinate system, ensuring best optical performance and minimizing coupling losses. This enables efficient light coupling by Free Space Microoptical Coupling (FSMOC).

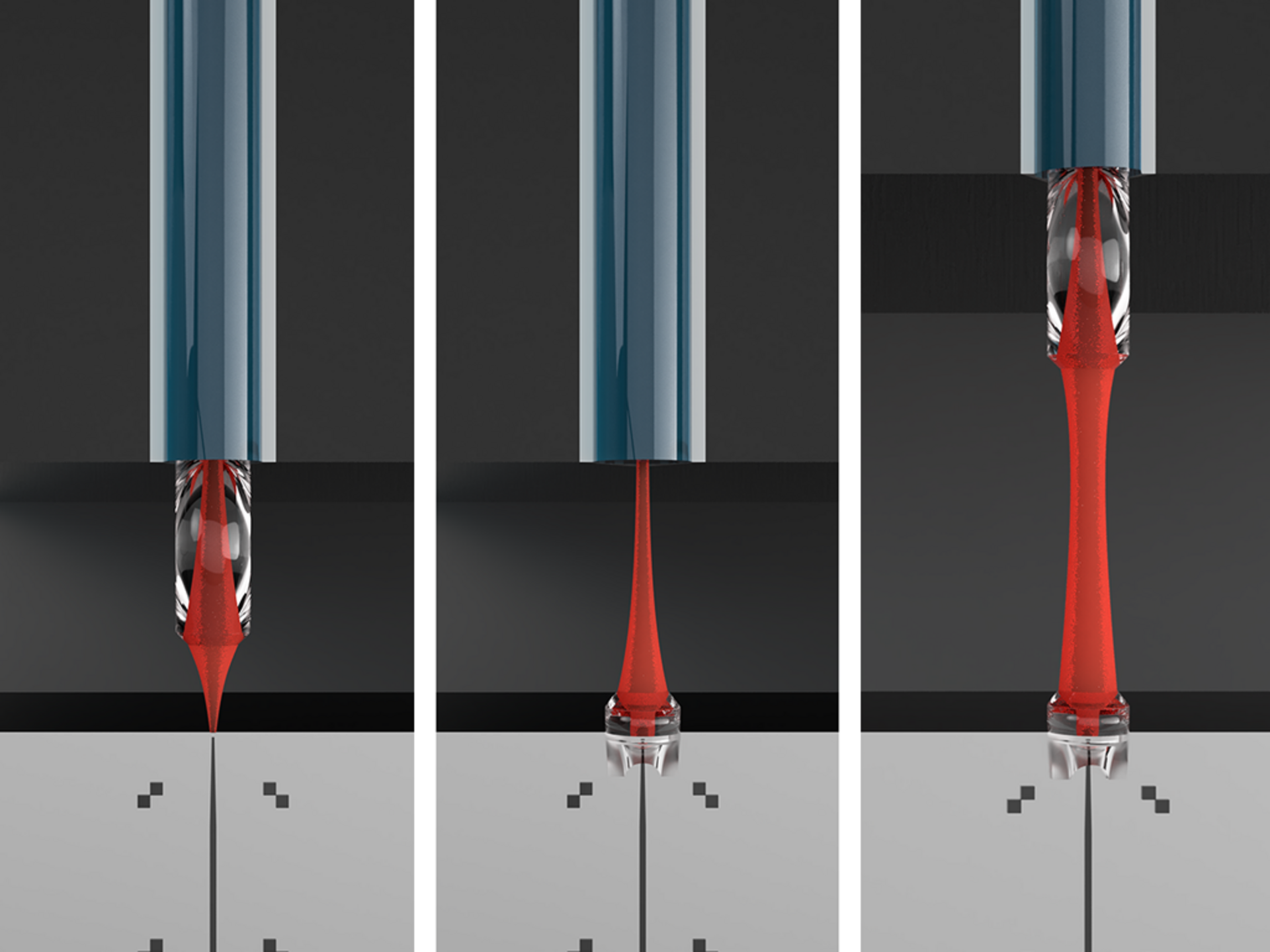

How to print edge couplers on photonic chips?

Printing onto a chip’s edge from the top, i.e. perpendicular to the substrate surface, is a challenging task. It requires both a highly precise positioning system and specific solutions to compensate for the “shadowing effect”: When printing onto a facet, a substantial part of the intensity in the focal point of the printing laser is blocked by the chip edge, reducing intensity at the focal point. This effect becomes more pronounced near the substrate wall and demands higher exposure doses.

To overcome this, Quantum X align uses a patented technology for dose compensated printing lenses on chip edges. During the printing process, the system automatically adjusts laser power through a proprietary dose compensation feature. As a result, microoptics and other print objects are printed onto the facet of a substrate with submicron accuracy.

What’s the role of nanoPrintX in fiber printing?

The fabrication of lensed fiber arrays (LFAs) and aligned prints on optical fibers with individual designs is enabled by the close interplay of hardware and software. With nanoPrintX, lensed fiber arrays (LFAs) can be created in just a few steps: Select the fiber node in the scene graph, place individual lens designs on the fiber as .STL or .OBJ files or through a parametric lens formula.

Multiple copies of the same print can be easily generated, or each fiber can be customized with an individual design. The finalized print project is then uploaded to the Quantum X align, where it can be started via touchscreen or remotely through nanoConnectX.

After a fast coarse alignment, the virtual fiber positions are matched with the actual fiber positions detected by the system. The aligned print then starts fully automatically – combining high precision with ease of use.

Quantum X align

Let's explore your possibilities

Still on the search? Discuss your questions with Jochen, our product expert, in a no-obligation 20-minute meeting.

We also invite you to schedule a personalized product demonstration, online or on-site, to experience the power of Quantum X align.