Basics and principles

What makes Two-Photon Polymerization the highest resolution 3D printing technology?

Two-Photon Polymerization, also known as two-photon or multi-photon lithography or direct laser writing, utilizes the basic physical effect of two-photon absorption. Two-photon absorption occurs when an atom or molecule absorbs two photons simultaneously, allowing it to be excited to a higher energy state. The medium is typically a liquid resin that is photosensitive and can be cured by UV light. 2PP printing uses light with lower energy, for example in the near-infrared range (NIR), which causes the printing material to solidify only if the photoresin molecules simultaneously absorb the energy of two photons. This mechanism is only likely in the focal volume of pulsed light because it requires a high light intensity inside a volume of the photosensitive material.

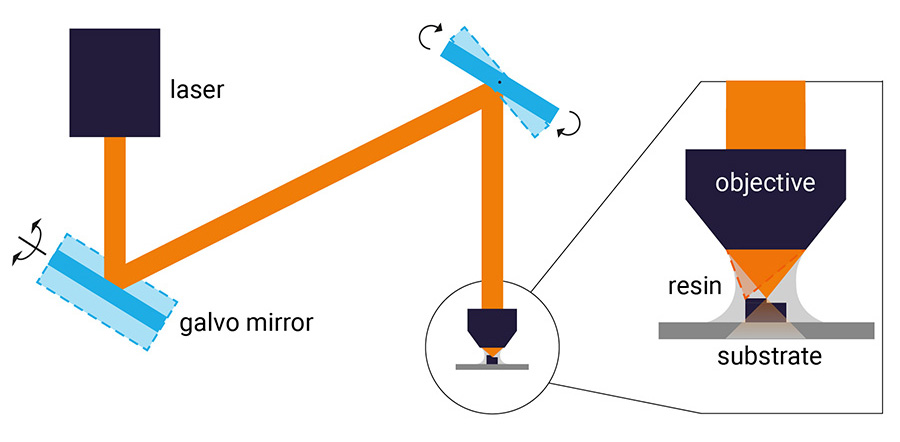

For fast and precise printing, galvo scanners move the focal point in the focal plane at speeds of hundreds of millimeters per second. In addition, in Two-Photon Polymerization nanofabrication and microfabrication systems a state-of-the-art stage with nanopositioning capabilities in all three dimensions moves the substrate with the photoresin to build up complex 3D microstructures.

By means of an objective lens, with Two-Photon Polymerization a pulsed laser beam is focused into a very tight volume inside a photosensitive material. Even though the average power of the laser might seem quite low, the laser emits ultrashort light pulses that contain a high photon density.

Tackling the challenges in high-precision 3D printing

When you prepare a print job from a CAD model to a final part, the 3D design will be converted to horizontal layers (slicing distance) and parallel lines (hatching distance). The microfabrication of a curved surface can be challenging, because it requires to split the design into several layers with a very small distance between them to avoid staircasing and achieve smooth surfaces. The printing of a high number of layers implies a longer print time for the structures.

Nanoscribe’s Two-Photon Grayscale Lithography (2GL®) technology, launched in 2019 and subject to Nanoscribe’s proprietary intellectual property, offers a more efficient solution to drastically reduce the number of layers and the overall print time of exceptionally smooth structures.