Multi-level diffractive optical elements

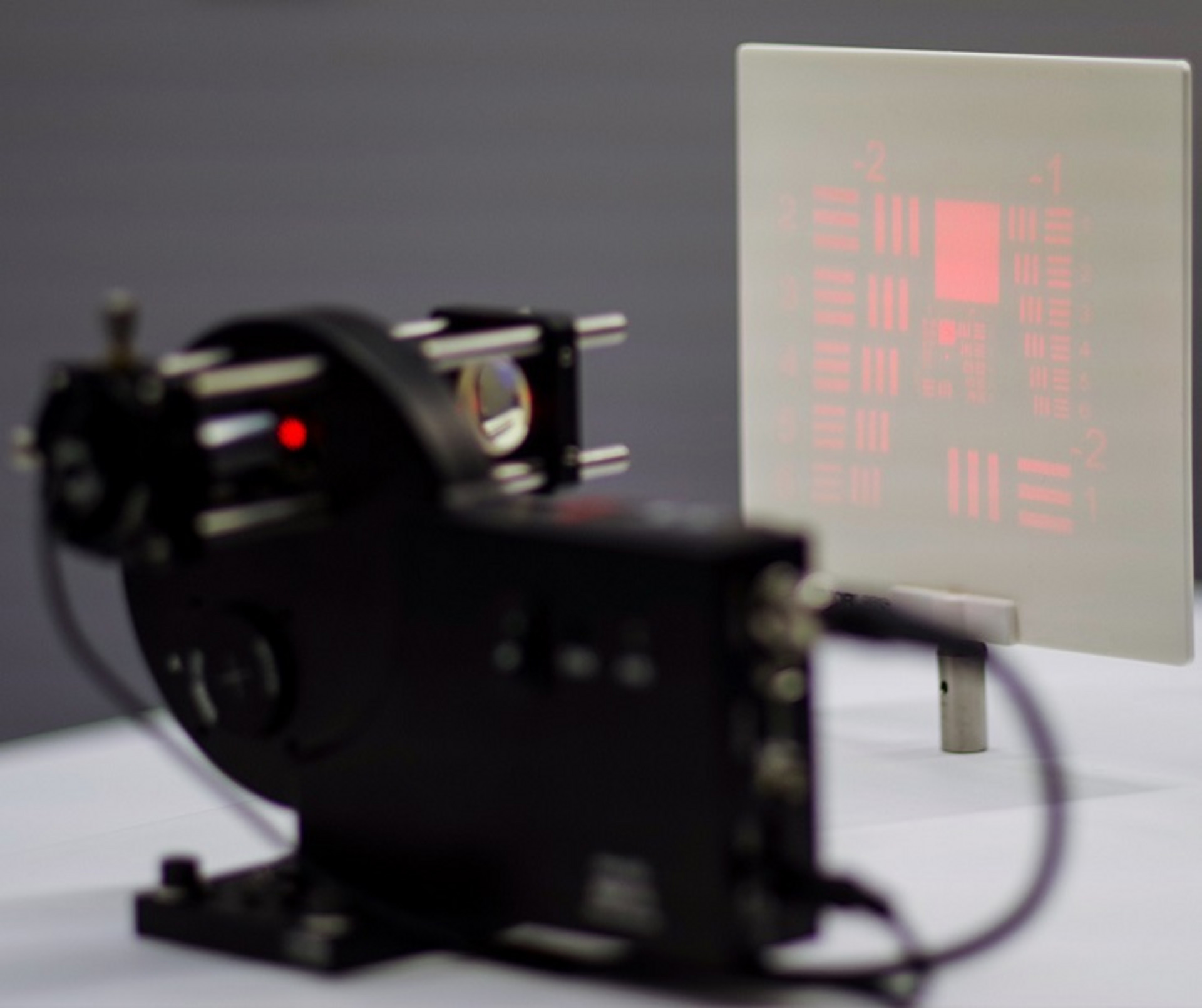

Two-Photon Grayscale Lithography enables the fabrication of multi-level diffractive optical elements (DOE) with truly outstanding shape accuracy in one printing step. The nanostructured surfaces meet the high lateral and axial submicron resolution needed in DOEs.

Nanostructured DOEs with excellent shape accuracy

The classical fabrication of diffractive optical elements (DOEs) was quite time-consuming and costly owing to multiple lithographic, etching and alignment processes. With additive microfabrication multi-level DOEs can be fabricated in one printing step, either as prototypes for direct use or as masters for tooling in volume production.

For the fabrication of DOEs we recommend Nanoscribe Quantum X litho. This system offers a maskless lithography solution, meeting the high lateral and axial resolution needed in DOEs. With the use of Two-Photon Grayscale Lithography (2GL ®), Quantum X litho directly fabricates multi-level diffractive optical elements in a single layer. Up to 4,096-level designs can be processed into discrete or quasi-continuous topographies in a cost-effective process.

Diffractive patterns with up to 4,096 levels

Diffractive microoptics

application opportunities

Looking to assess the opportunities for your diffractive microoptics project? Explore the application options of our microfabrication solutions and view the 10 most recent scientific publications in materials engineering from over 2,100 peer-reviewed journal articles.

To view the details of the publications and to find more research topics and applications in which Nanoscribe printing systems are successfully used, just enter our premium resources - log in or register for free.

View more innovation projects

You get more publication examples and deeper insights within our premium resources. Via a keyword-underpinned database you find more than 2,100 scientific publications of our customers in specific application areas. Make use of the tool to gather valuable know-how and background information about the manifold application options.