From idea to biofabrication –

with your high-resolution 3D bioprinter

Quantum X bio for high-resolution

3D bioprinting on the scale of cells and tissues

The Quantum X bio is a highly versatile, high-resolution 3D bioprinter powered by Two-Photon Polymerization (2PP). It enables the fabrication of detailed structures from subcellular to millimeter scale and supports sterile printing for biomedical research, tissue engineering, and microfluidics.

3D biofabrication for life sciences

Quantum X bio precisely prints organic designs and complex 3D structures into microfluidic chips and onto diverse substrates, using biomaterials from Nanoscribe, our partners or custom sources. Essential features like temperature and humidity control, a premixed air/CO₂ connection and HEPA-filtered airflow create a well-regulated environment, with the filtered airflow ensuring sterility. The high-resolution 3D bioprinter Quantum X bio is the optimal 3D biofabrication tool when resolution, precision, speed, biocompatible materials, and sterility are essential.

Bioprinting library and smart workflow

With Quantum X bio, you benefit from Nanoscribe’s intuitive software with touchscreen control, enabling easy print setup, execution, and monitoring — either directly on the device or remotely via nanoConnectX. The Bioprinting Model Library offers a growing selection of verified 3D designs to simplify your entry into high-resolution bioprinting. Continuous logging of temperature and humidity ensures cell-friendly conditions throughout the printing process.

See what’s possible

with the highest precision in 3D bioprinting

Quantum X bio in facts and figures

Included features

-

High-resolution bioprinting process with feature sizes down to ≤ 1 µm for subcellular structures based on Two-Photon Polymerization (2PP)

-

CO₂, temperature, and humidity control with heatable cell culture dishes enabled by Bioprinting Set

-

Access to the Bioprinting Model Library

-

Holders for a wide variety of substrates such as microscope slides and cell dishes

Optional features

-

Rapid and accurate surface patterning enabled by Two-Photon Grayscale Lithography (2GL®)

-

Printing relative to fiducials/markers or chip edges, to support e.g. printing in microfluidic channels using Aligned 2-Photon Lithography (A2PL®)

-

Up to 60 times faster speeds at superior quality compared to classic 2PP, achieved through 3D printing by 2GL® (Two-Photon Grayscale Lithography)

| Feature size control | down to 100 nm in x/y direction |

| Stitching-free part diameter | up to 4,000 µm |

| Maximum scan speed | 6.25 m/s divided by lens magnification |

| Live cell printing viability | > 90% |

Given values may vary depending on the photoresin and structure geometry.

| Substrates | Microscope slides / microfluidic chips (3” x 1” / 76 x 26 mm2) Cell culture imaging dishes (35 mm or 50 mm) Various flat substrates up to a size of 100 x 100 mm2 Glass, silicon, and further transparent/opaque materials, and coated/uncoated substrates |

| Photoresins | Nanoscribe photoresins (polymer printing) Nanoscribe GP-Silica (glass printing) Open for third-party or custom materials Hydrogel bioresins from Advanced BioMatrix and BIO INX |

Quantum X bio features –

engineered for scalable 3D bioprinting success

Prof. Budd Tucker, University of Iowa (US)

The Photonic Professional GT system was great for tinkering and research, but it is cumbersome. The Quantum X bio is 1,000x better, and I am glad I bought it – I have never looked back.

In-chip printing –

where 3D bioprinting meets microfluidics

Built on a powerful 3D microfabrication system based on two-photon lithography, Quantum X bio provides the flexibility and precision required for aligned 3D bioprinting on a variety of substrates. This includes printing into microfluidic systems, MEMS chips, and multi-electrode arrays (MEAs) for applications in organ-on-a-chip, lab-on-a-chip and organoid research.

With advanced features for in-chip printing, you can fabricate high-resolution structures precisely aligned to specific substrate geometries:

- Direct printing into custom or commercial microfluidic channels and wells

- High-aspect-ratio 3D structures precisely aligned to open channels or cavities

- Intuitive touchscreen “tap-to-align” with collision prevention for safe operation

- Compatible with Nanoscribe resins, partner materials, or custom biomaterials

- Ready-to-use designs in the Bioprinting Model Library

Software

Enjoy the usability of Quantum X bio

Field-proven 3D bioprinting software for cutting edge life science applications

How do you get from your 3D design to the final 3D printed structure. Nanoscribe’s software solutions facilitate users the streamlined preparation of print jobs. Generate, upload, print, and monitor your print job directly from the device’s touchscreen or remotely from your PC.

Create your 3D print job with DeScribeX or nanoPrintX: We offer two powerful software solutions, each designed to meet your specific needs. The 3D print job development software DeScribeX takes you from 3D CAD model import to print job upload in just a few steps. It’s intuitive and easy with print preview and simulation.

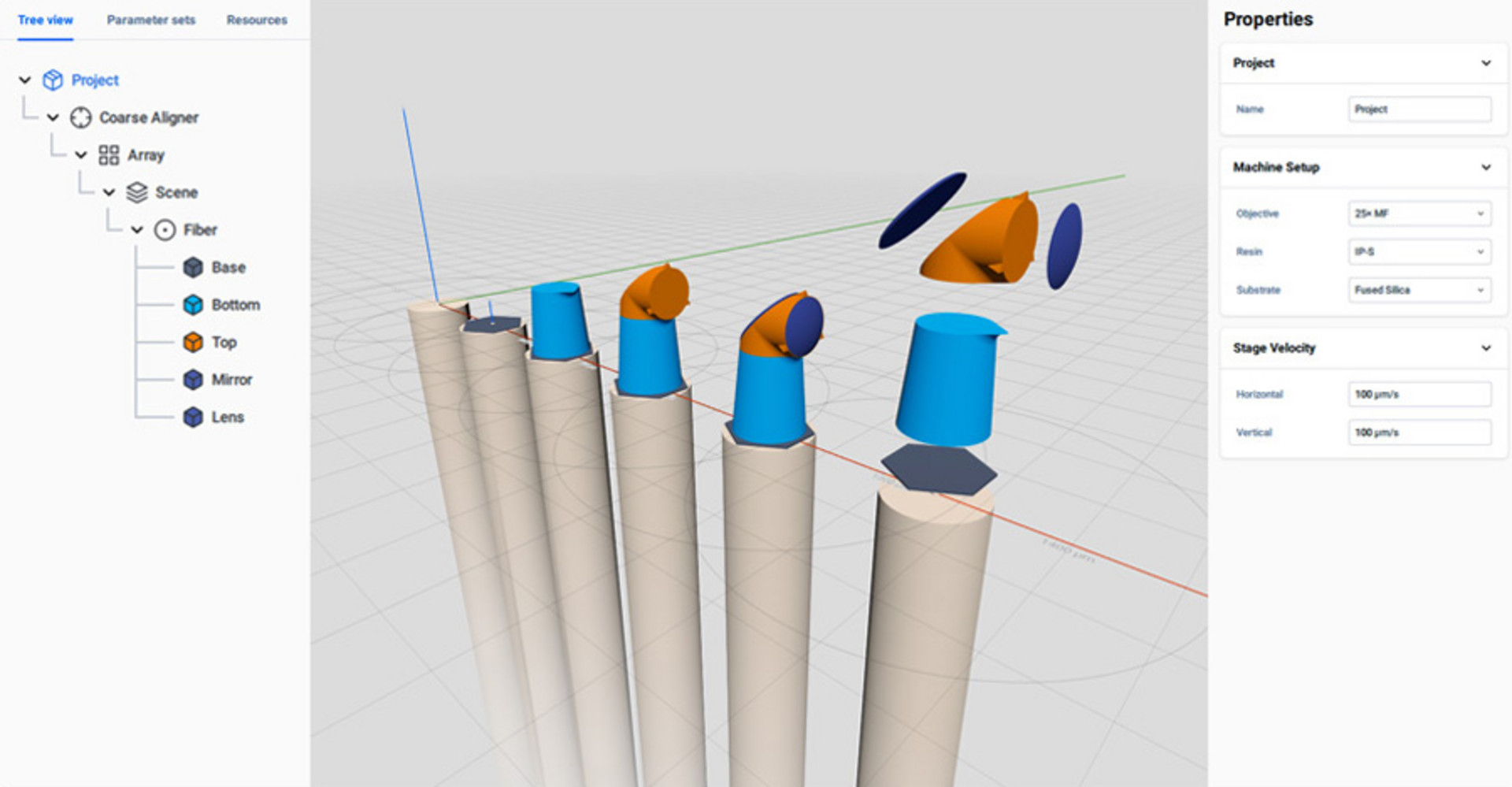

Compose your own customized print project with nanoPrintX. Define the print scenario by creating a virtual model of your specific substrate, import your 3D print designs or use pre-installed simple geometries as building blocks. Assign pre-developed print parameters to individual parts of your design as needed. nanoPrintX is powered by our latest printing technology, 3D printing by 2GL®, delivering superior quality at unrivaled speed.

Get inspired by the Bioprinting Model Library from CELLINK and Nanoscribe: Benefit from a comprehensive library of proven STL models that you can download and customize. This makes it really easy to print successfully.

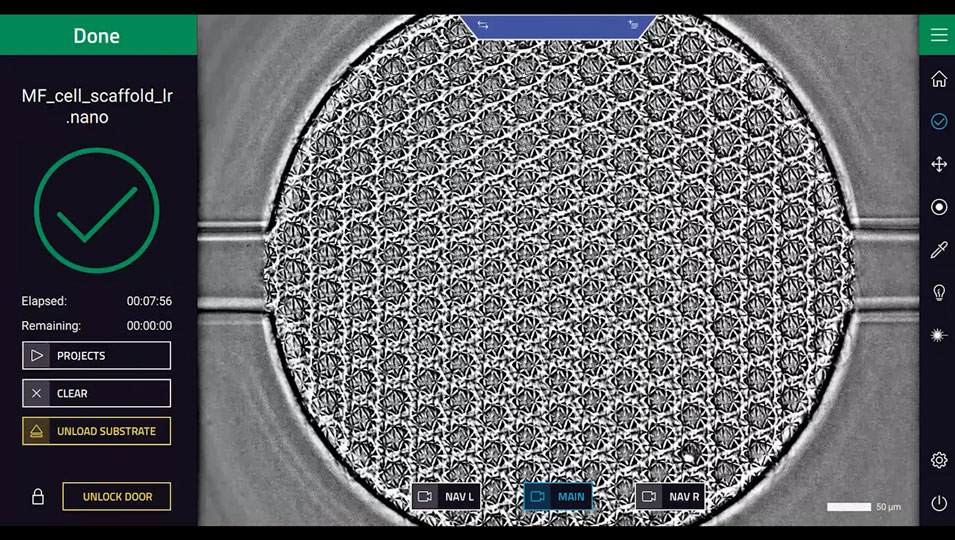

Start your print job from the touchscreen: Quantum X bio’s intuitive touchscreen menu will guide you to a successful print job. Also benefit from key information such as hardware information, system status and printing progress. In addition, a live view of the printing process via three cameras gives you visual control at any time.

Stay connected with nanoConnectX: Start and monitor your print job from the office with nanoConnectX remote access software. This makes the high-resolution 3D bioprinter Quantum X bio ideal for multi-user facilities.

Software facts

Benefit from a comprehensive library of STL models provided jointly by CELLINK and Nanoscribe. Instead of spending hours creating designs in CAD, simply select a design from our database, download it and customize it to your needs. The designs provided are inspired by biological and biomedical applications. The designs are scalable, so you can use them not only on the high-resolution 3D bioprinter Nanoscribe Quantum X bio but also on other bioprinters such as CELLINK’s BIONOVA X or BIO X6. This is your fast track to printing success.

DeScribeX is a print job development software for creating custom 3D prints. The built-in import wizard can load STL files as a widely used 3D CAD format. Pre-installed software printing parameter presets are perfect starting points that guide you to a successful print in just a few steps. The export function makes it easy to transfer the print job to the Quantum X bio remotely.

| Key feature | Benefits |

| 3D CAD model import wizard | Intuitive workflow generates suitable print job files from standard STL files |

| Print parameter presets | Ready-to-use preset parameters for optimal printing results right out of the box |

| Adaptive slicing | For surface refinement and improved shape accuracy |

| Parameter sweep | Easily find the perfectly matching print parameters for new materials and applications |

| Integrated Development Environment (IDE) | Experts can create and modify print files (GWL) for custom and sophisticated printing tasks |

| 3D preview and printing simulation | What you see is what you print! DeScribeX displays parameters such as print time, scan speed or laser power and simulates the entire printing process in detail |

nanoPrintX is available for all Quantum X systems. It enables easy and fast design of complex structures and offers special printing strategies for specific parts of a structure. It also supports structure-substrate aligned printing with nanometer precision and is powered by our latest printing technology, 3D printing by 2GL®, delivering superior quality at unrivaled speed.

Structures ranging from the submicron to the millimeter scale can be fabricated using nanoPrintX. Its easy-to-use tree node organization guides you in a few simple steps to set up print projects for aligned prints on optical fibers, on photonic chips and other pre-patterned substrates.

Key features

- 3D rendering canvas for composing and positioning structures relative to each other or to fiber cores, fiducials, and chip edges

- Easy creation of array configurations

- Intuitive organization of all print relevant operations in a tree node

- Ready-to-use parameter presets for optimal print results

- 3D printing by 2GL® for superior quality at unrivaled speed

- Fiducial detection via pattern matching

- Dose compensation for excellent results on substrate edges

- Fiber printing node for automatic fiber core detection and printing of optical structures

- Parametric lens design tool based on ISO standard 10110

nanoConnectX is the remote access software for the Quantum X systems. It brings all the functions and display capabilities of the touchscreen to any computer connected online.

| Key feature | Benefits |

| Remote access to the system | Connect Quantum X bio to your computer, wherever you are |

| Use all features of the touchscreen | Prepare, control and monitor your print jobs from anywhere |

| Upload and download print jobs and reports | Access print-related files directly from your computer |

Dive into 3D bioprinting

and learn how Quantum X bio works

How to best perform cell culturing experiments?

For cell culturing or cell seeding applications, microstructures are first printed using a material such as hydrogels or one of Nanoscribe’s biocompatible photoresins. After printing, the structures are rinsed and cells are seeded onto the structures. Typically, the substrates are kept in incubators to monitor cell behavior over time.

Cell seeding is the most common technique used to combine 2PP-based microfabrication with cell research. Our publication database in the premium section of the website provides inspiration for research projects using Nanoscribe technology.

As an example of a cell seeding application, we printed 100 µm diameter microwells from IP-S and seeded them with NIH 3T3 fibroblast cells. The image below shows an animated vertical image stack of the stained cells in the microwells:

How is Quantum X bio enabling live cell printing?

Live cell printing involves direct laser writing with living cells embedded in the resin. Keeping cells alive during the process is a challenge due to physical and environmental stress. Quantum X bio supports you with:

- Bioprinting chamber for a sterile conditions with temperature and humidity control

- HEPA-filtered airflow and a connection for premixed air or CO₂

- Support for hydrogel-based bioresins

- Cell-friendly wavelength (780 nm)

- Fast printing speeds to minimize stress

- Standard 3D designs available in Bioprinting Model Library

Live cell printing with 2PP is still rare, but this high-resolution 3D bioprinter is built to make it possible. The following structure was printed from a gelatin methacrylate-based bioresin loaded with NIH 3T3 fibroblast cells. We demonstrated a cell viability of >90%. The image series shows that the cells are alive and truly embedded in the printed structure.

Which materials are compatible with Quantum X bio?

A wide range of biocompatible materials is available for use:

-

Nanoscribe photoresins e.g. IP-Dip, IP-S, IP-Q, IP-PDMS, IP-Visio, IPX-S, IPX-Clear, IPX-Q & IPX-M

-

Nanoscribe GP-Silica fused silica glass printing

- Nanoscribe ’s partner-provided hydrogels & biomaterialse.g. Hydrobio INX N400 (BIO INX) and PhotoHA (Advanced BioMatrix)

- Third-party and custom materials

Note 1: The Quantum X bio high-resolution 3D bioprinter is designed as an open material system and allows you to use your own or third-party materials, tailored to your application.

Note 2: Nanoscribe also offers other photopolymer resins for Quantum X bio that enable a wide range of non-medical applications.

Why choose Quantum X bio over other bioprinters?

The print speed metric refers to the number of voxels printed per second and is an indicator of how digital information is converted into solidified material. The graph shown here compares Two-Photon Polymerization (2PP) to common additive manufacturing technologies in terms of printing rates and feature sizes. Measured by the absolute volume printing rate of 2PP, the serial process appears to lag behind the speed of other technologies. However, the technology features a high voxel printing rate compared to the fine voxel sizes it resolves.

Our whitepaper provides deeper insights into the performance of various high-resolution 3D printing technologies. You can find it in the premium section of our website. Log in or register for free.

Why is Quantum X bio ideal for shared facilities?

The high-resolution 3D bioprinter Quantum X bio is ideal for shared facilities because it supports many substrates and materials, meeting a variety of research needs. Its intuitive design lets users start printing right away, even if they are new to the system. Excellent technical support and the online NanoGuide, where you can quickly look up information, make it even easier for everyone to use.

Quantum X bio software controls and monitors high-resolution 3D bioprinting jobs in real time and supports intuitive operation via an interactive touchscreen control panel, or remotely from the office via nanoConnectX remote access software.

Quantum X bio

Let's explore your possibilities

Still on the search? Discuss your questions with Jochen, our product expert, in a no-obligation 20-minute meeting.

We also invite you to schedule a personalized product demonstration, online or on-site, to experience the power of Quantum X bio.