3D microfabrication for materials engineering

Material properties can be tailored by material composition and by geometric design. Benefit from highest shape accuracy and performance of our 3D microfabrication solutions to innovative metamaterials and bioinspired microstructures with specific photonic, mechanical, biological or chemical properties.

3D printing of microstructures with complex functional designs

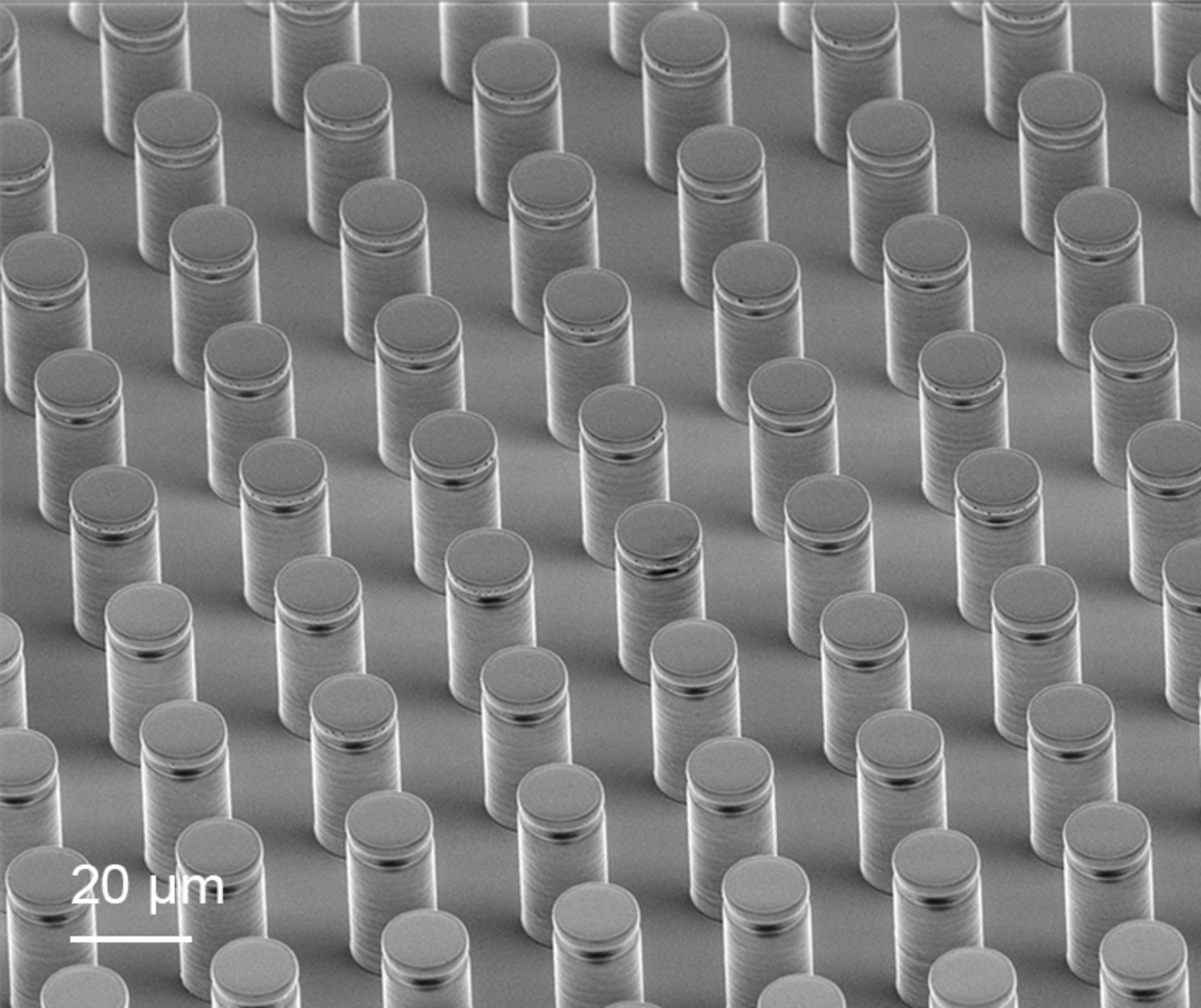

3D microfabrication allows to create materials with tailorable mechanical, photonic or plasmonic response by structuring. For example, photonic crystals or metamaterials such as circular broadband polarizers or perfect absorbers for the mid-IR range were developed with this technology. Mechanical metamaterials also benefit from the geometrical design freedom that determines mechanical properties, ranging from damage tolerance to ultralight weight and unusual twisting response.

Both Nanoscribe 3D printers, Quantum X shape and Photonic Professional GT2 offer ease of use and enormous design freedom to print delicate structures with minimal sizes typically on the submicrometer scale. Application examples also include photonic, plasmonic and mechanical metamaterials as well as biomimetic nano- and microstructures, e. g. superhydrophobic surfaces and photonic structural colors.

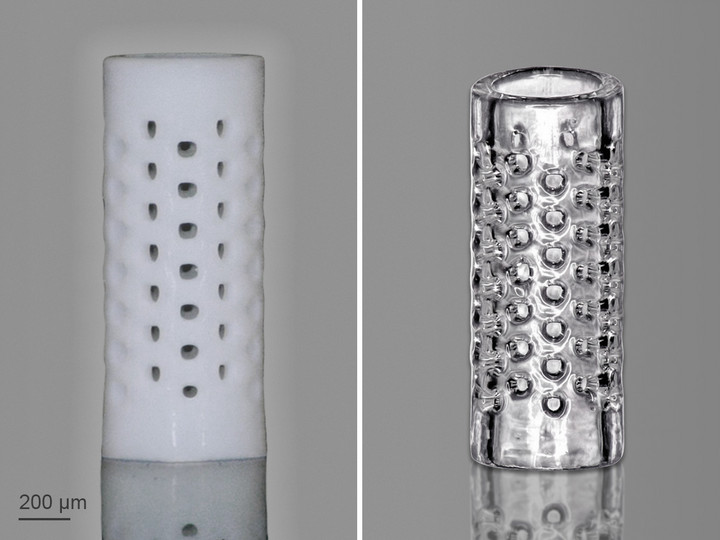

The choice of printing materials is decisive for the quality, function and performance of the final printed microstructures. It determines final qualities such as resolution, surface roughness, specific chemical, mechanical or optical properties. Our IP photoresins benefit from a careful selection of starting chemical systems adapted to Two-Photon Polymerization and are tailored to specific applications. For example, IP-PDMS is a soft and highly elastic photoresin for a wide range of applications, such as 3D-printed cell scaffolds and tissue engineering, 3D-structured surfaces, microfluidic devices or microelectromechanical systems (MEMS). With GP-Silica Nanoscribe offers the first photoresin for 3D printing silica glass microstructures. High optical transparency combined with thermal, mechanical and chemical stability enable to explore new applications.

Get inspired by 3D microfabrication artworks

Materials engineering

application opportunities

Looking to assess the opportunities for your materials engineering project? Explore the application options of our 3D microfabrication solutions and view the 10 most recent scientific publications in materials engineering from over 2,100 peer-reviewed journal articles.

To view the details of the publications and to find more research topics and applications in which Nanoscribe 2PP-based 3D printing systems are already successfully used, just enter our premium resources - log in or register for free.

View more innovation projects

You get more publication examples and deeper insights within our premium resources. Via a keyword-underpinned database you find more than 2,100 scientific publications of our customers in specific application areas. Make use of the tool to gather valuable know-how and background information about the manifold application options.