There is great interest in the pharmaceutical industry in producing effective and cost-effective tailor-made drugs. Lipid nanoparticles containing poorly soluble drugs are promising candidates that can be more easily assimilated by the body or delivered bypassing the gastrointestinal tract. An essential condition is that they provide a much faster dissolution rate. However, the strategies for producing these lipid nanoparticles are challenging. They involve several steps such as the preparation of the nanoparticles and incorporation of the drug carrier into the nanoparticles.

In the production of nanoparticles, it is important to manage narrow particle size distributions to achieve the required range of 70 nm and up to 200 nm. For this purpose, microfluidic systems offer an advantageous approach compared to bulk mixing techniques. Microfluidics offer precise control and tunability of mixing extremely small liquid quantities. Mixing in microfluidics enables nanoparticle fabrication, but this requires the use of more effective and complex mixing elements to tune nanoparticle properties and optimize the mixing mechanisms. By using Two-Photon Polymerization (2PP), freeform 3D microfluidic elements are developed and integrated into complex microfluidic chips. The use of this versatile 3D microfabrication targets the needs to narrow the particle size distribution.

3D printing of a complex microfluidic chip

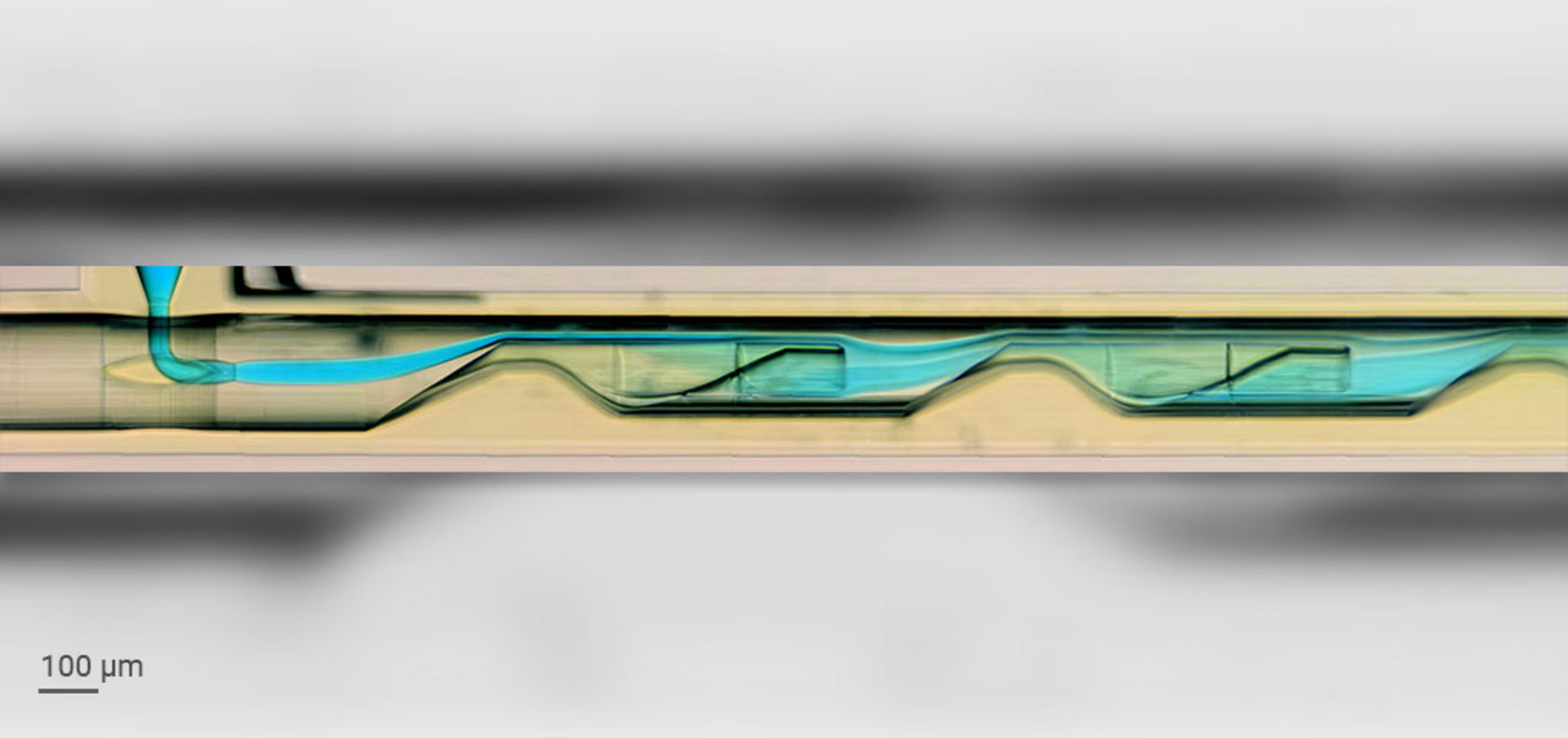

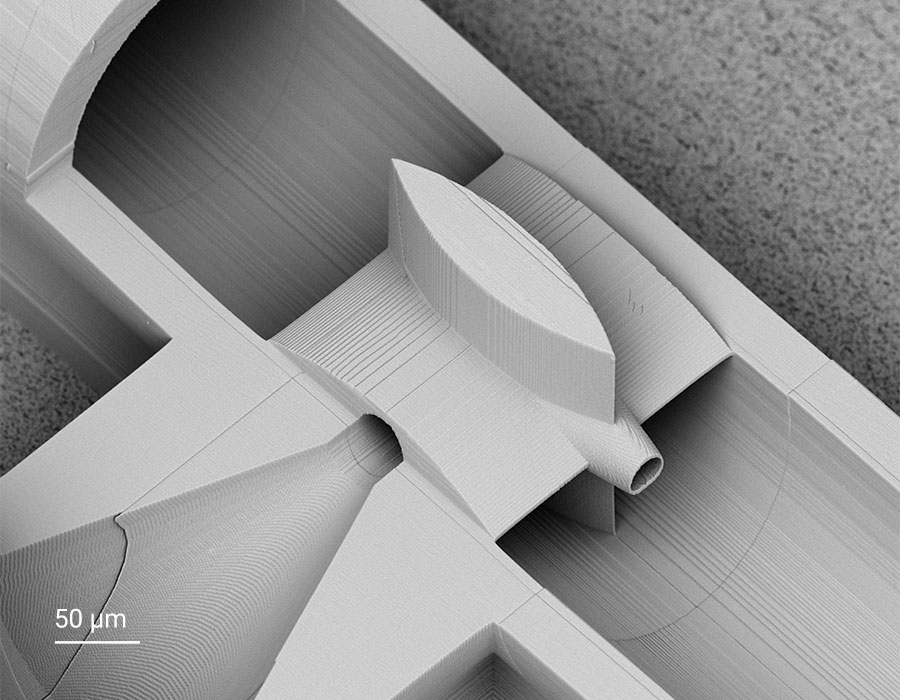

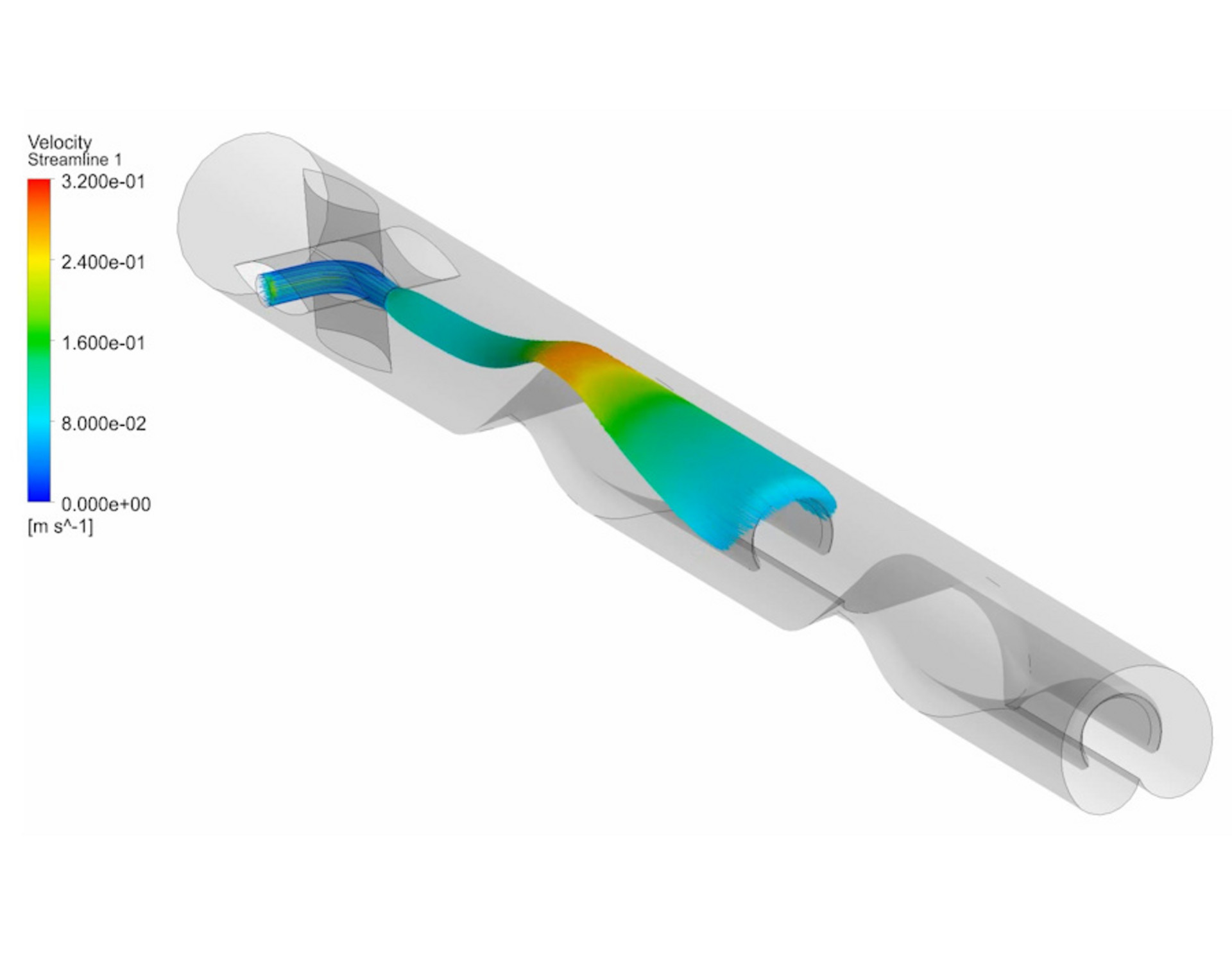

Scientists from the TU Braunschweig investigated a groundbreaking approach in the field of microfluidics to fabricate monodisperse drug carrier nanoparticles. They used Nanoscribe’s Two-Photon Polymerization capabilities to 3D print a complete microfluidic chip. The chip is designed with a unique micromixer for coaxial lamination and stable nanoparticle generation. The complete centimeter-long microfluidic chip consists of a main channel connected to a lateral channel, a nozzle for coaxial injection, a series of 3D mixing elements and inlet filters to reduce contamination. This sophisticated chip design stands out due to its miniaturized characteristics and high surface quality. For example, the inner diameter of the main channel is 200 µm and the inlet filters have a pore size of 15 µm. The stretch-and-fold elements feature an intricate 3D structure to mix the organic and aqueous phases. Conventional 2.5D microfabrication and mass production using micro-injection molding fail to produce this microfluidic system because the undercut structures and open cylinder areas are difficult to mold.

High reproducibility with high-precision 3D printing

The 3D-printed microfluidic system was designed to produce nanoparticles of defined size and with highest possible reproducibility. The identical design was tested with three separately fabricated microsystems. They show sufficiently small variations in the dispersity of the nanoparticle size in the range of a few nanometers. The results confirm the ability of 2PP-based 3D printing to produce highly reproducible nanoparticles with narrow particle size distribution. The findings are of great importance for the future realization of parallel nanoparticle fabrication.

Microfluidic elements reduce fouling with efficient mixing

The chosen microfluidic elements consist of a 3D structure that causes the injected organic stream to transversely being stretched and folded. This increases the interface between the two phases, organic and aqueous, as they flow through the channel, accelerating diffusion and mixing of the two liquids. At the same time, the stretching of the organic phase reduces the thickness of the stream. Both effects shorten the diffusion time and thus increases the mixing velocity.

Thanks to the 3D flow focusing by the injection nozzle and the coaxial mixing elements, the contact of the organic phase with the channel wall is avoided. In this way, the 3D-printed elements inside the chip prevent contamination, which is a main risk for reproducibility and continuous as well as parallel fabrication of nanoparticles.

If you would like to read more about this research project, you can find the complete scientific publication on this unique coaxial lamination mixer here.

This and further scientific publications on more than a thousand research projects from Nanoscribe customers and system users can be found in a powerful database with a keyword search in the Premium Resources section. Register for free to see for yourself the potential of Nanoscribe’s 3D Microfabrication technology for innovative applications and fundamental innovations in many areas, and to evaluate its suitability for your project.